Plasma cutting collision services offer advanced solutions for auto damages, especially complex repairs. This technology is precise, efficient, and beneficial for fleet repairs, preserving vehicle integrity and appearance with minimal heat input. It's ideal for detailed autobody work like removing damaged panels, straightening metal, and creating custom cuts while ensuring long-term asset value.

“In the realm of automotive repair, understanding common damages is key to efficient solutions. This article explores typical auto damage scenarios and highlights the significance of plasma cutting collision services. When conventional methods fall short, plasma cutting offers a precise, game-changing approach. We delve into how this technology becomes the optimal choice for repairing various metal panel damages, ensuring intricate and accurate repairs. Get ready to discover the process behind plasma cutting collision repair.”

- Understanding Common Auto Damage Scenarios

- When Plasma Cutting Is the Optimal Solution

- The Process of Plasma Cutting Collision Repair

Understanding Common Auto Damage Scenarios

Auto accidents can lead to a variety of damage scenarios, each requiring specific and effective repair solutions. Common auto damages include dents, scratches, crumpled fenders, shattered windshields, and more severe structural injuries. These incidents can occur due to collisions with other vehicles, obstacles, or even as a result of harsh weather conditions. Understanding these common damage types is crucial when it comes to selecting the right repair methods, especially in cases where traditional techniques might not be suitable or efficient.

Plasma cutting collision services have emerged as a game-changer in automotive repair, offering precision and efficiency for various types of auto damages. For instance, paintless dent repair techniques can restore cars to their original condition without the need for repainting, saving time and costs. Fleet repair services also benefit from plasma cutting technology, ensuring quick turnaround times and maintaining the safety and integrity of commercial vehicles.

When Plasma Cutting Is the Optimal Solution

When it comes to addressing complex auto damages, plasma cutting collision services stand out as an optimal solution. This advanced technique is particularly effective for repairs that involve intricate shapes, tight spaces, or precise cuts in vehicle body repair. Unlike traditional cutting methods, plasma cutting offers exceptional accuracy and control, making it ideal for detailed autobody repairs.

Plasma cutting’s versatility makes it a game-changer when dealing with various types of auto damages. It is especially useful for removing damaged panels, straightening bent metal, or creating custom cuts during dent repair processes. This method ensures minimal heat input, preserving the structural integrity and original appearance of the vehicle, which is crucial for maintaining the overall value of the asset in the long run.

The Process of Plasma Cutting Collision Repair

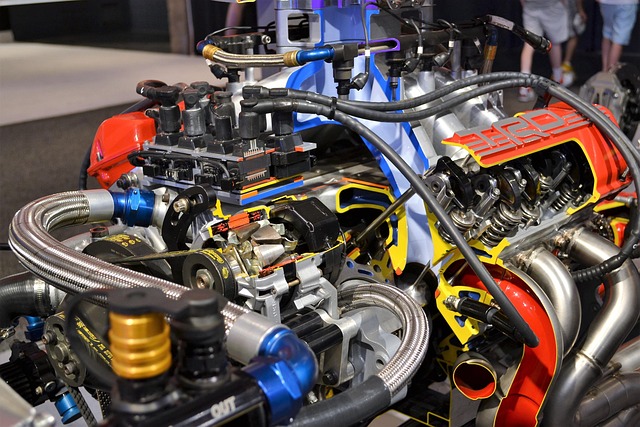

Plasma cutting collision repair is a specialized process that uses plasma arc technology to cut and shape metal accurately. This advanced method is particularly useful for auto body repairs, especially when dealing with complex geometry or tight spaces. The process begins by preparing the damaged area, ensuring it’s clean and free of debris. A plasma torch, powered by an inert gas mixture, is then used to create a high-temperature arc that cuts through the metal with precision.

This technique offers several advantages for bumper repair and car paint services. It allows for intricate cutting patterns, making it ideal for restoring vehicle components to their original specifications. Moreover, plasma cutting minimizes heat impact on surrounding areas, preserving the structural integrity of the vehicle’s body and reducing the risk of warping or melting during the repair process. This ensures that autobody repairs are not only efficient but also reliable and long-lasting.

In addressing common auto damages, plasma cutting collision solutions offer a highly effective and precise method for repairs. By understanding specific scenarios where plasma cutting is optimal and navigating the process efficiently, professionals can ensure top-quality restoration. This advanced technique not only enhances structural integrity but also preserves the vehicle’s original aesthetics, making it a go-to choice for modern auto body shops.